NAV×

Description

The versatility of the best Horizontal Hydraulic Press Machine makes it possible for us to make a great deal of forging parts and all kinds of operations in all kinds of materials: pipe, flat bar, several profiles, rods... Folding operations with wrought iron machines permit to completely bend the parts or pieces unlike conventional flat bar section bending machines. Pipe bending at fixed radius up to 180º could be considered one of the other good features of these presses. Stretching and reducing pipes on the ends in order to make parts that fit or weld later. Cutting, piercing and punching flat bars or metal sheets turn this horizontal bending press into a punching shears machine. Many workshops use these presses to stretch and form different kinds of profiles. It is also a solution to bend different profiles at different radius and keeping the ends straight, like when manufacturing handles and flanges. Pipe notching to assemble to another one at 90º. Cold forge uses horizontal presses to make and form different shapes of balosters... Its versatility and its easy handling make this machine a necessary horizontal bending machine for metal working processes. Technical features Horizontal Bending Press Brake PP200 has been manufactured in a 60mm thick welded steel monoblock, stabilized and mechanized. Its robustness, versatility and easy handling are just three of the best features our hydraulic horizontal bending machine has. ADVANTAGES • - Easy handling: The machine is sent completely assembled, it is only necessary to connect it to the required power supply and start performing.

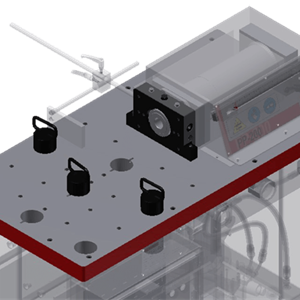

Main technical parameter table:

1. Paameter

(1) Punching

Maximum punching force: 125T

Punching processing range: Φ4.3~Φ25mm

Punching die position: 4/6

Maximum processing thickness: 12mm

Maximum processing width: 160mm

(2) Shearing

Maximum shear force: 125T

Maximum shear thickness: 12mm

Maximum cutting width: 160mm

(3) Bending processing

Maximum bending force: 125T

Maximum bending thickness: 16mm

Maximum bending width: 160mm

2. Dimensions: 1500×1300×1300 (length×width×height)

3. Table size: 1200×800×900 (length×width×height)

4. Motor power: 4KW×3 sets (three stations can work at the same time)

5. Machine weight: 1000KG

PRODUCTS VIDEO

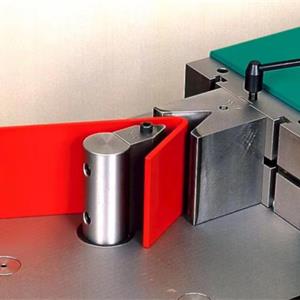

Standard mold list

| Name | Amount | Size |

| Punching mold | 8 units | Diameter OD 80, 90, 100, 110, 120mm |

| Shear | 1 | 160mm blade |

| Cross bending die | 2 | convex R3R8,concave40mm80mm |

| Stand bending die | 1 | Convex R30R80,concave120/240/350mm |

| height | 350mm(3 pistons with full cylinder) |

| Embossing Die | Optional |

| Press cable mould | Optional 4 sets |

| U bending die | Optional |

Download Zone

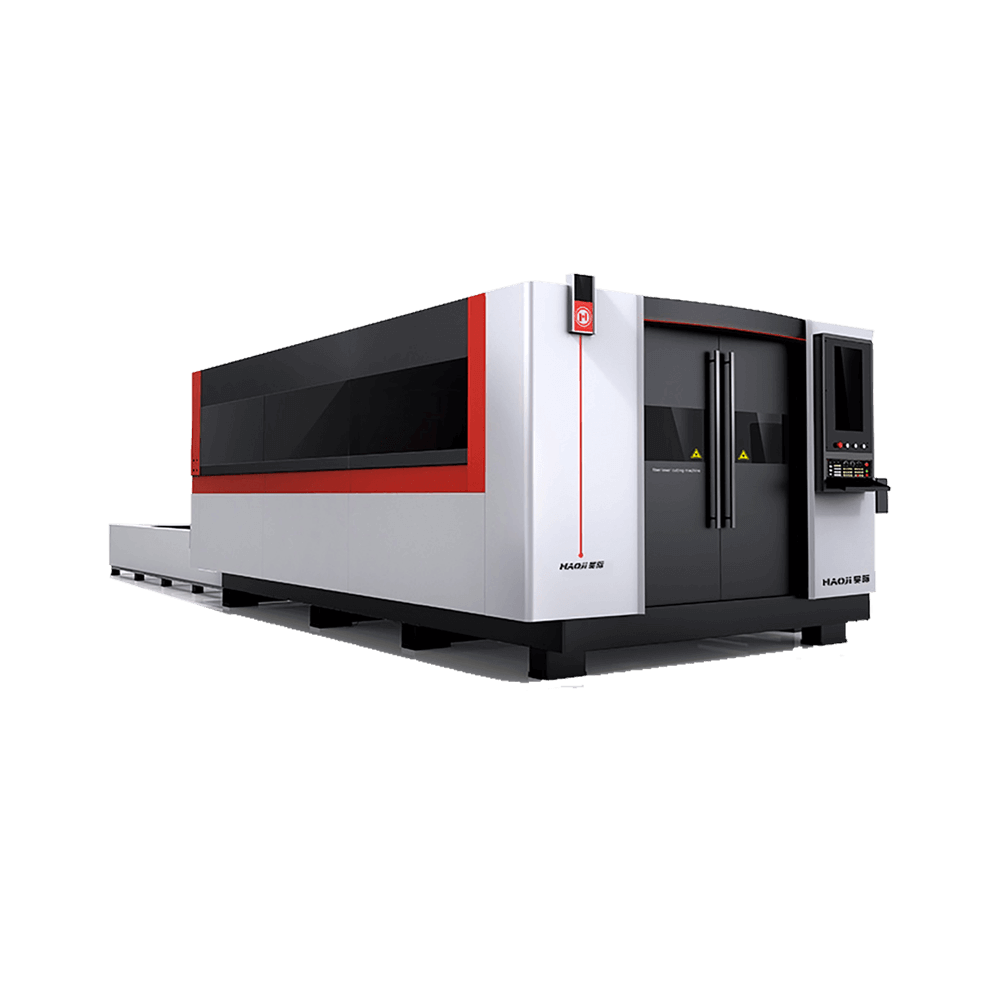

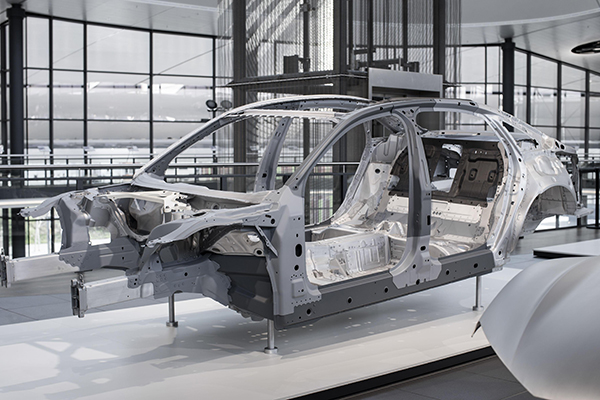

More downloadsApplication industry

Kitchen appliances,sheet metal case cabinets,machinery equipment,electrical equipment,lighting hardware,advertising signs,auto parts,display equipment,various metal products,sheet metal cutting and processing industries.